From yarn to fabric the Albini Group monitors and ensures the highest quality of each stage. After finishing the fabrics are subjected to strict controls at the laboratory of Gandino.

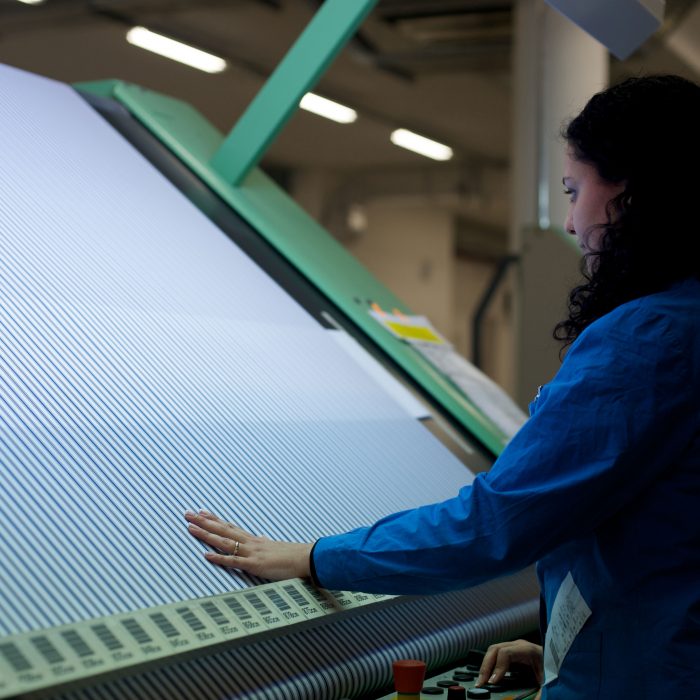

Once back from finishing the fabrics are re-checked at 100% under the magnifying glass. The inspectors closely monitor the fabric and their extensive know-how guarantees the highest quality. When the observation control is completed the fabric passes over for laboratory tests, with both physical and chemical tests being carried out.

The fabric testing laboratory of Albini Group is accredited by ACCREDIA, the only Italian National Body appointed by the State to perform accreditation: this formalises the recognition of competence to perform specific laboratory tests in accordance with UNI CEI EN ISO / IEC 17025 “General requirements for the competence of testing and calibration laboratories”. Awarded to an internal laboratory of a textile firm for the first time in Italy, this accreditation represents for Albini fabrics a real guarantee.

The chemical testing trials the properties of the fabric in the different conditions of use, ensuring colour fastness to dry rubbing, washing and distilled water. Also its resistance to acid or alkaline perspiration and to washing with detergent or perborate. Finally, it passes to the hydrolysis of the reactive colours, oxygenation agent, optical brightness, and the pH test. The physical tests instead verify that the fabric possesses a resistance such as to allow the correct sewing make up and the use of the finished garment, such as the slipping at the seams and tear strength, abrasion and tearing. They also certify the stretchability and the dimensional stability to washing and steam.