The path that our raw materials travel to become the splendid fabrics of the Albini Group’s brands is a fascinating and complex one, into which we put all our passion, commitment and technology.

With the Albini Group, direct control over each production phase is fundamental for ensuring superior quality. Our vertically integrated production chain allows us to maintain high quality standards, enhancing the value of each production phase through in-depth understanding and control over the operations.

The quality of our fabrics begins with researching and selecting the finest natural raw materials. We directly control and carefully select the most precious cottons and linens, establishing partnerships with local growers.

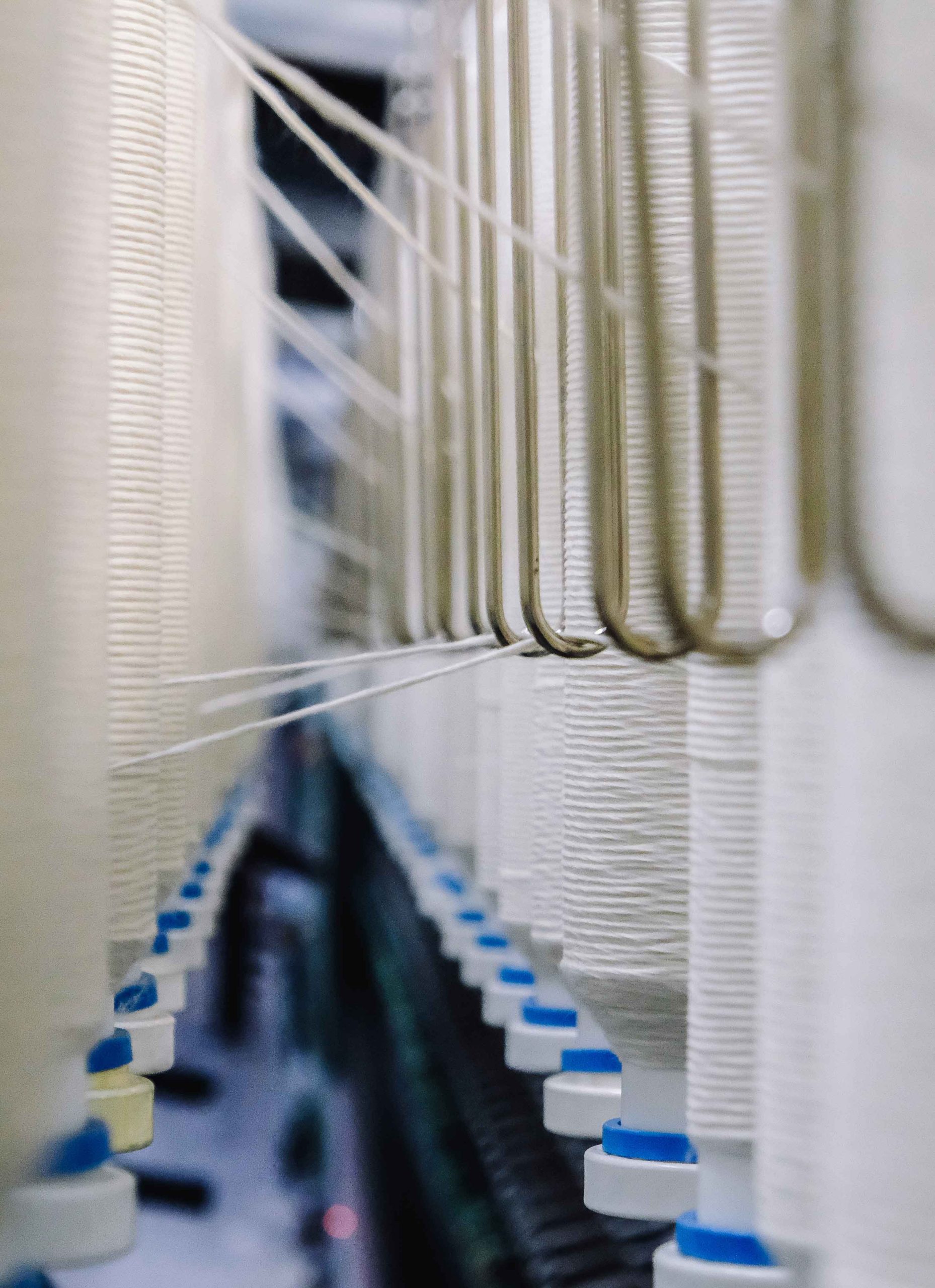

After carefully selecting the raw materials, we transform the fibre into yarn through the spinning process. Albini Yarns is in charge of carrying out this process, ensuring superior yarn quality control. Additionally, we also deal internally with new yarn research and development.

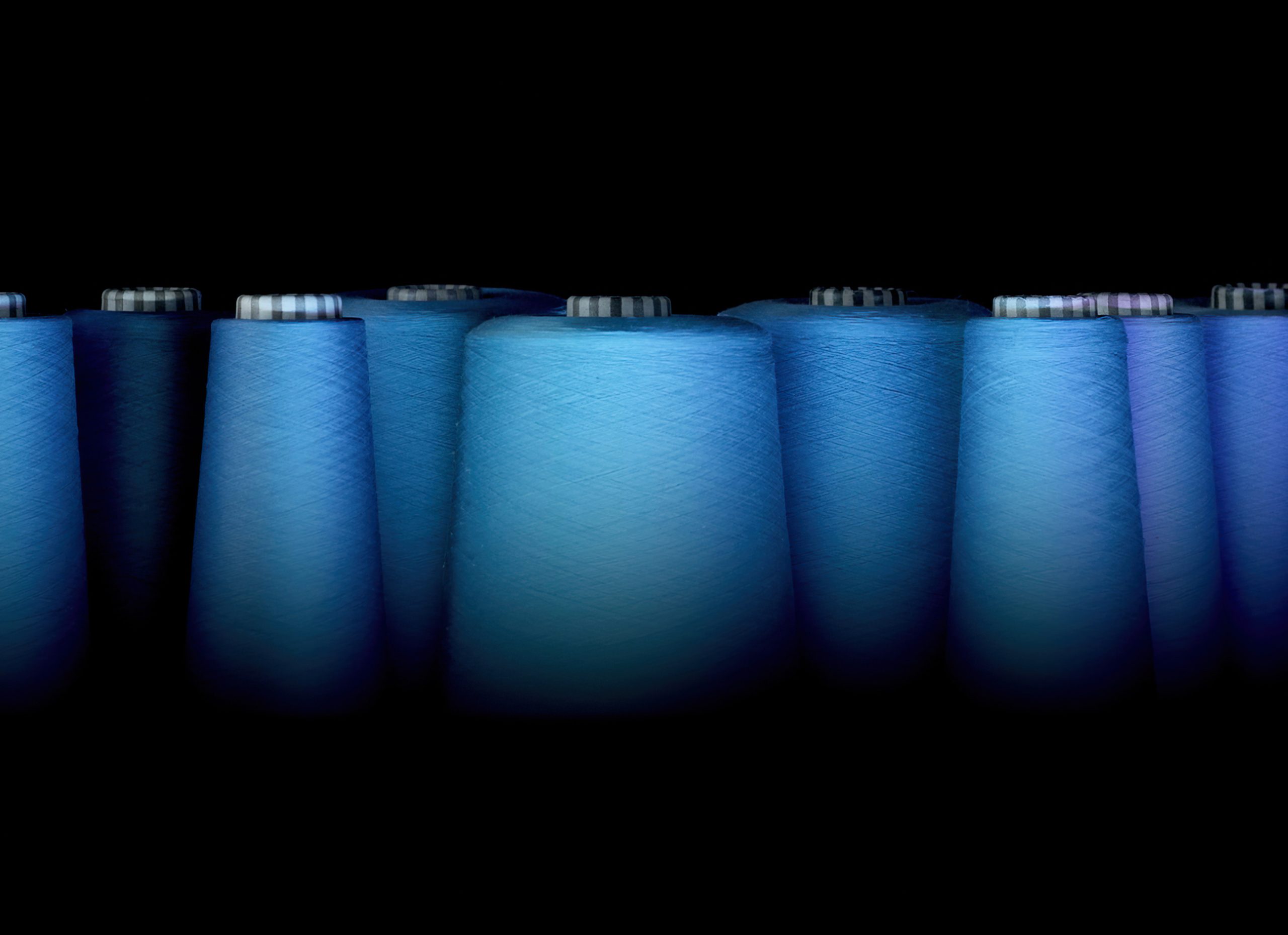

Yarn dyeing takes place in our dyeing plants: this allows us to exercise continuous controls over the process and the dyed yarns, ensuring that the result is consistent with our quality standards. State-of-the-art machinery and technology allow us to obtain excellent results with considerable savings in energy resources.

Our in-house laboratory studies and creates customised dyeing formulas for each customer and conducts laboratory testing to verify performances

The weaving process transforms yarns into fabrics, weaving together the weft and the warp. This phase is the sum of the quality of the raw materials, the creativity of the design and our staff’s experience.

Owing to the advanced machinery and our experts’ know-how, we operate on three production sites with uniform quality standards, dealing with diverse raw materials in a specific way.

A crucial phase of the production process, finishing gives the fabric its appearance, hand and desired performances.

The fabrics are finished in the Group’s production plants: that is why we are able to provide customised service for the demands of each customer.

The final controls consist of a series of strict physical and chemical tests that ensure the maximum quality of the finished fabric. These tests are conducted in our in-house laboratory accredited by Accredia.

Each metre of fabric is also visually checked at the final inspection.

We also handle logistics in-house, with a semi-automated warehouse for yarns and fabrics and RFID tracking technology, to ensure that each delivery is handled efficiently and in a timely manner.